|

|

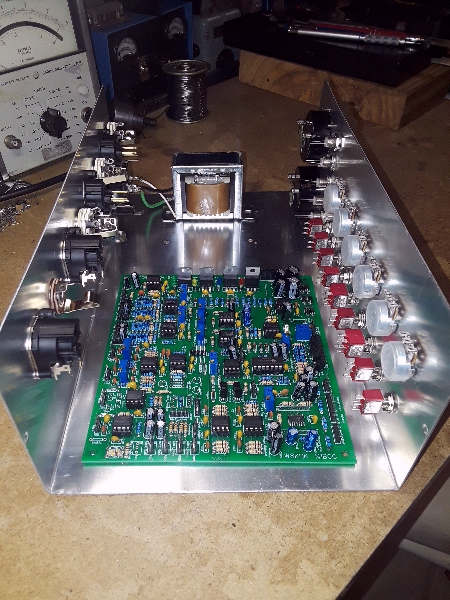

| The MAX Audio Processor For Amateur Radio, LPAM, And Podcasting | |

| HOME ||| INTRO ||| GALLERY ||| ASSEMBLY INFO ||| CALIBRATION ||| MOD INFO ||| SCHEMATICS |

|

Information contained on these web pages copyright W8KHK / N1BCG. Amateur or individual use is encouraged. Commercial use of any kind is prohibited without the express written permission of the author, Richard A. Maxwell The "MAX" Audio Processor Assembly Information - General Guidelines

(Read this section before proceeding with component insertion and soldering. It is also STRONGLY RECOMMENDED

that the builder review the entire customization documentation found at the "MOD INFO" link before starting

construction. The choice to install headers or trim-pots, and other components, is dependent upon the builder’s

preferences for controls and other options!) Errata document below deserves a peek before heating up that

soldering iron!

Audio Processor Errata Version 4.02 PDF

1) Organized by Component Value for parts acquisition and inventory

While most component number legends are visible on the silkscreen after parts are soldered, the multitude of

resistors obscure their R### designation. Therefore, having a printout of the board silkscreen legends might

prove very helpful while populating the fixed resistor components. A printable image of the board silkscreen

is available under the "GALLERY" link.

After deciding which functions are desired, it is suggested that the builder mask unnecessary parts on the

parts list.

Also note that there are customization variations in the input microphone preamplifier circuits to allow the

use of many types of microphones with no external adaptors, transformers, or modifications. Please review

these options and record the planned installation procedure before proceeding.

An important Note regarding "phantom power"

for microphones:

The input circuits do not include any source of phantom power. If microphones which need phantom power are

contemplated, it will be necessary to use an external source between the microphone and the processor. The

rationale for this design decision focuses on minimizing the potential for expensive microphone damage due

to variations in kit building. The designers of this device assume no responsibility for microphone damage

if the builder attempts to add a phantom power source to the circuit.

|

|

Special note for the experienced custom builders

If no other customizations are desired, proceed with assembly instructions

below. The default configuration via the parts list provides for two low-level, balanced microphone inputs.

If any specialized customizations are desired, such as balanced line in/out inserts (Send and Return) are planned

for other audio chain components, please study the customization section to ensure correct component selection and

header access to enable these functions. Enabling flexibility of customization has been planned during the product

design phase.

Following the suggested “Board Assembly Sequence” ensures ease of mounting components flush with the printed

circuit board.

By mounting the lowest, smallest components first, the board may be inverted, and the work surface will retain

the components flush against the board while soldereing.

Solder one or two lands of the multiple-connection components, and verify the component is flush with the board

surface and in proper alignment before soldering the remaining connections. |

|

Component insertion and soldering instructions

IMPORTANT! The SSM2166 can be damaged by static

discharge. Be sure to discharge any static buildup on yourself before handling the board!

Note: Trim-pots, selected fixed resistors, capacitors, and header installation requirements may be altered by

customization decisions, which should be reviewed first to avoid the need for changes if components are installed

unnecessarily. Depending upon choice of options, some components MUST NOT be installed!

Install components in the following order:

1 [__] Solder the surface-mount Compressor/Limiter chip (SSM-2166). (Note that pin ONE is on the side of the

chip which has a beveled edge along the top from pin 1 to pin 7 end.) When finished soldering, visually check for

shorts between the pins. Then use an ohmmeter to check continuity between each pin and the adjacent header test points.

Finally, use the ohmmeter to check for shorts between adjacent pins, probing the header connections adjacent to

the compressor IC.

It is suggested that Resistor R310 NOT BE INSTALLED along with all the other resistors. Instead, wait until

power supply regulator output voltages are verified, thus protecting the SMD compressor chip. Install R310

just before installing all the socketed integrated circuit devices.

Optionally you may use an SMD carrier, (not supplied) with male header pins, then install female headers when

the other headers are installed, and then later plug the carrier to the main board .

2 [__]All signal and power diodes - Observe polarity band.

3 [__]All fixed resistors EXCEPT R310. (Please refer to safety note in step 1 regarding the compressor chip)

To reduce the chance of placement errors, start with large groups of same value resistors, ie, 10 K ohm. In

order to easily identify resistor values after assembly, it is customary to orient resistors so that color

codes all read from left to right, or from top to bottom.

4 [__] All Integrated Circuit Sockets - All IC sockets have the orientation notch (pin 1) toward the top of the

board.

5 [__] All “Dupont” pin headers (male and female) Note: Male and Female Dupont Headers are cut to length

(by builder) from 40 pin raw stock. See detailed information below to properly configure the

required male and female headers. When installing multiple-pin headers, notice the silkscreen has a (box) painted

around pin 1. This is obscured when installing either male or female header strips. Also note that the header

identifier (matching the identifier in the schematic diagram) is always printed close to pin 1. Other silkscreen

information near the header is either a pin-by-pin signal ID list, or a general function identification for that

specific header.

It is STRONGLY RECOMMENDED that the builder review the entire

customization section before installing any headers or trim-pots.

Make notes in your parts list to avoid incorrect placement of headers or trim-pots before soldering!

Male and Female Header selection and installation:

Female headers should be installed at:

6 [__] (Optional) POWERBUS: 6 pins (for measuring regulator outputs)

7 [__] (Optional) POWERMON: 6 pins (for measuring pre-regulator outputs or calibrating SCAF Clock)

8 [__] LEDS: 10 pins (for connecting GAIN GATE, NEG, POS, NORMAL, and PEAK panel-mounted LEDs via Dupont wires)

9 [__] (Optional) P102: 7 pins (test points for compressor chip signals)

10 [__] (Optional) P103: 7 pins (test points for compressor chip signals)

11 [__] (Optional) PETP: 4 pins (test points for pre-emphasis signals)

12 [__] (Optional) CLPTP: 4 pins (test points for clipper signals)

Three Pin Male Headers should be installed at:

13 [__] H01: Microphone input one

14 [__] H02: Microphone input two

15 [__] H03: Line Input one

16 [__] H04: Line input two

17 [__] H05: Line output one

18 [__] H06: Line output two

19[__] H07: Utility outputs

20 [__] H51: Line output one negative signal pad (optional, may use wire jumper if attenuator pad or DC blocking capacitor will never be used)

21 [__] H52: Line output one positive signal pad (optional, may use wire jumper if attenuator pad or DC blocking capacitor will never be used)

22 [__] H61: Line output two negative signal pad (optional, may use wire jumper if attenuator pad or DC blocking capacitor will never be used)

23 [__] H61: Line output two positive signal pad (optional, may use wire jumper if attenuator pad or DC blocking capacitor will never be used)

24 [__] ACIN: AC transformer connection, pin 1: common = center-tap, pins 2 and 3: start and end of secondary

25 [__] VPOS: Voltage selection for Balanced Line Out circuits (Recommend jumper from "12" to "out" instead of voltage selection header.)

26 [__] VNEG: Voltage selection for Balanced Line Out circuits (Recommend jumper from "12" to "out" instead of voltage selection header.)

The following may have either three-pin male headers to interconnect front-panel pots, or on-board

trim-pots may be used to semi-permanently set the input and output levels. (Normally the inputs are front-panel

controls and the outputs are on-board trim-pots.)

27 [__] R10: Microphone one gain control

28 [__] R20: Microphone two gain control

29 [__] R38: Line one input gain control

30 [__] R48: line two input gain control

31 [__] R241: Utility output one level

32 [__] R251: Utility output two level

33 [__] R261: Line output one level

34 [__] R281: Line output two level

Customization / Configuration Note: The seven headers PHZ, LCF, APF, PE, CMP, SCAF, and CLP are provided to allow

control of signal flow through the chain. Each of these sections may be excluded from the signal path by connecting pin

2 to pin 3, or included in the path by connecting pin 3 to pin 4. This may be accomplished as a preset configuration by

placing a jumper on the header pins, or it may be configured at will via a SPDT switch, connected to the header via

Dupont wires (both included in the kit.) Normally a switch is not used for either CMP or CLP, as discussed later.

Pin 1 is a ground connection, provided in the event shielded cable is desired for longer distance runs. The short

Dupont wires do not normally require any shielding.

The spacing of the headers in group PHZ through CLP is such that a single 40 pin male header may be cut to 34 pins in length,

and every "fifth" pin may be carefully extracted from the plastic, allowing a neat installation of these seven "four-pin" headers

as one component!

Four Pin Male Headers should be installed at:

35 [__] PHZ: Invert phase of signal path - Header for switch or Berg jumper

36 [__] LCF: Low-Cut Filter enable/disable - Header for switch or Berg jumper

37 [__] APF: All-pass filter (phase rotator) enable/disable - Header for switch or Berg jumper

38 [__] PE: Pre-Emphasis enable/disable - Header for switch or Berg jumper

39 [__] CMP: Compressor / Limiter enable/disable - Header for switch or Berg jumper, Berg jumper is recommended, Compressor Options controls are normally sufficient

40 [__] SCAF: Switched-capacitor audio filter enable/disable - Header for switch or Berg jumper

41 [__] CLP: Clipper enable/disable - Header for switch or Berg jumper, berg jumper is recommended, CLIP% controls are normally sufficient

42 [__] CLIP%: Configure clipper behavior - Header for switch is required here

43 [__] BW: Bandwidth control (frequency selection for SCAF clock) - Header for switch is required here

Builder Note: Even if you have decided upon a permanent configuration for any or all of the above options,

using headers and jumpers (instead of hard-wired jumpers) greatly improves the ability to perform calibration

and troubleshooting tasks, conveniently enabling you to isolate each individual stage for any required

measurements or signal insertion.

An eight pin male header should be installed at:

44 [__] Gate Noise Comp Lim Resp: Configure compressor options - will be wired to panel switches

45 [__] INP: Configure input summing options

46 [__] OUT: Configure output signal distribution options

47 [__] All .1 uF disk bypass capacitors U###N and U###P designation.

48 [__] All other non-polarized capacitors - Depending upon vendor, wires may need to be adjusted to fit with PCB

hole spacing.

49 [__] All trim-pots - MUST REVIEW CUSTOMIZATION SECTION prior to installing headers or any

trim-pots! Note the position of the adjustment screw on the silkscreen and align accordingly. If this

requirement is not met, then the adjustment screw will need to be turned opposite to the normal direction for level

decrease or increase. See detailed information below to properly configure the required male and female headers.

Hint: Normally trim-pots are appropriate for the following components: R14, 24, 31, 41, 134, 135, 136, 162, 184, 241, 251, 265, and 285.

50 [__] All electrolytic capacitors - Observe correct polarity using the white negative marking, or the long lead to

+ legend.

51 [__] All transistors - Solder transistors with ¼ to ½ inch lead exposed. Do not mount transistors flush with PC

board surface.

Please see the note in the errata bulletin (Link Button Above) regarding the proper

orientation of transistor Q181!

52 [__] All power status LEDs - Adjacent to their respective regulator ICs.

Please see the note in the errata bulletin (Link Button Above) regarding the proper

polarity of the positive five volt indicator LED!

53 [__] All 78xx/79xx linear regulators - The metal tab is oriented close to the edge of the board as in the

silkscreen legend. Heat sinks are provided and may be installed at any convenient time.

Note: the regulators are normally mounted vertically above the PCB, and soldered on the bottom. However, it is

possible to heat-sink the regulators by mounting them on the bottom of the enclosure, to the left of the PCB.

Bend the last ¼” to 3/8” of the leads up at a 90 degree angle, insert the pins into the PCB from the bottom, and

solder the center pin of each regulator at the top side of the PCB. Secure the PCB to the enclosure with 3/8”

standoff hardware. Then drill the bottom of the enclosure and mount the regulators, Finally, solder the

remaining regulator leads to the top of the PCB. If the regulators are heat-sinked in this manner, the

negative regulators must be insulated from the metal enclosure. It is actually preferable to insulate all four

regulators, in the interest of eliminating any ground loops. (There should only be one ground point to the

chassis, and that should be at the lowest-level input connector. Considering the input power connector passes

AC to the on-board rectifiers, the common power input lead should also be isolated, and not grounded to the

enclosure.)

54 [__] Apply AC Power via 12 volt (2-wire) or 24 volt center tapped (3-wire)transformer secondary.

55 [__] Resistor R310: install to provide power to compressor/limiter SMD component.

56 [__] Verify Power Supply Voltages at IC Sockets:

Measure from ground to the following sockets for positive five volts (plus or minus 1/4 volt):

Measure from ground to the following sockets for negative five volts (plus or minus 1/4 volt):

Measure from ground to the following sockets for positive twelve volts (plus or minus 1/4 volt):

Measure from ground to the following sockets for negative twelve volts (plus or minus 1/4 volt):

57 [__] Install socketed Integrated Circuits:

Board Assembly Completed! Now you may proceed to CALIBRATION!

The component portion of the PCB is assembly is now completed. It may be desirable to test the modular

functionality, or, if you wish, you may proceed with the enclosure preparation and component mounting prior

to performing electrical verification. |

|

Perform enclosure layout plan; mark locations and drill for all

components with these considerations

A suggested front-panel layout might include a row of option switches

low on the panel, and input gain potentiometers and other controls above the row of switches. Left would be the

two microphone input gain controls, and to their right the line input gain controls. Far right might be the

bandwidth and compressor controls.

The five LED indicators may be grouped in a vertical or horizontal arrangement. The blue LED indicates predominant

negative peaks in the mix, while the green indicates predominant positive peaks, which of course are preferred in

AM transmission. The yellow LED indicates normal input level to the compressor, and should be illuminated almost

continuously while talking, and the red Peak LED indicates the compressor is in operation and it should be

illuminated occasionally. Note: Vertical orientation appears similar to the familiar traffic stop-light configuration,

and thus is easily interpreted. Version 4 of the processor adds the "Gain Gate" feature, with a WHITE LED indicator

illuminating during speech pauses.

Plan to install connectors near to their respective headers on the printed circuit board. For example, when viewing

the enclosure from the rear, place the output connectors on the left, the line inputs in the center, and the

microphone inputs on the right. The power connector should be near the far left, as distant from low-level microphone

inputs as possible. If using an external AC transformer for a power source, be sure that the common lead is NOT

connected to the chassis or enclosure, thus eliminating one source of "Ground Loops".

Be sure to allow for clearance between board and components entering from the front and rear panels. This can be

accomplished by allowing sufficient vertical clearance between bottom of panel component, and the devices which rise

above the surface of the PC board.

Review locations of connection headers on board to allow easy access for wiring after the connectors and controls

are installed. If an over-sized enclosure is chosen, for example, a 1U rack enclosure, then front and rear panel

components may be far removed from the circuit board, and clearance conflicts are virtually eliminated. For smaller

enclosures, clearance requirements should appear rather obvious. Connection cables may be groups of wires, as needed,

with the exception of the high-impedance microphone input for ceramic, crystal, i.e. D-104 microphone input connections.

This low-level, high impedance connection requires shielded cable to minimize hum and noise. |

|

Prepare a careful, symmetrical and aesthetically pleasing layout, then

punch and drill for

1) Connectors

Note: Connectors may be any combination of XLR, TRS, RCA, or terminal strips, as desired. XLR and TRS connectors may be

connected in parallel to add flexibility and eliminate the need for adaptors.

Mount all components

Cut wire and/or use “Dupont wires” to solder or plug each component wire to respective headers on the board. |